Hardware Development

Overview of Hardware Development

We are dedicated to supporting local hardware tech startups and businesses with specialized electronic product development services. We collaborate closely with clients to turn their ideas into high-quality, functional electronics tailored to their needs. Our expert team streamlines the development process, accelerating time-to-market and enhancing competitiveness. Committed to fostering local innovation, Run Automations Ltd is a catalyst for growth in Uganda's tech ecosystem.

Our Hardware Development Services

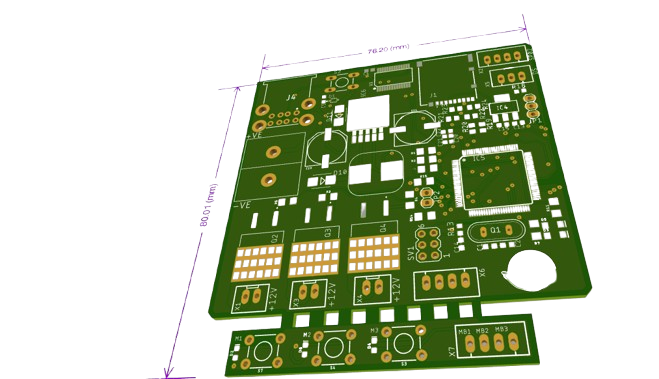

Custom PCB Design

We provide tailored PCB design services to ensure optimal performance and efficiency for your embedded systems.

Prototyping and Testing

Our prototyping and testing services guarantee that your hardware meets all necessary standards and specifications.

Firmware Development

We develop efficient and reliable firmware that integrates seamlessly with your hardware solutions.

Our Hardware Development Process

Requirement Analysis

We collaborate with clients to gather and analyze all requirements, ensuring we understand the project needs.

Design & Development

Our team designs and develops customized hardware solutions that meet industry standards.

Prototyping

We create prototypes to bring concepts to life and allow for adjustments before full-scale production.

Testing & Validation

Each prototype undergoes rigorous testing to ensure functionality, safety, and compliance with regulations.

Production

Once validated, we move forward with production, delivering high-quality, reliable hardware solutions.

Frequently Asked Questions

1. What is the typical timeline for hardware development?

The timeline for hardware development can vary based on project complexity, but typically ranges from a few weeks to several months. Factors influencing the timeline include design specifications, prototyping, testing, and production requirements.

2. What are the costs associated with hardware development?

Costs for hardware development depend on various factors such as project scope, materials, and complexity. We provide detailed quotes after assessing your project requirements to ensure transparency.

3. Can you assist with product certification?

Yes, we can guide you through the product certification process to ensure compliance with industry standards and regulations. Our team has experience with various certifications necessary for market readiness.

4. Do you provide support after the hardware is developed?

Absolutely! We offer ongoing support and maintenance services to ensure your hardware continues to perform optimally after deployment.

5. What is your approach to prototyping?

Our prototyping approach is iterative, allowing for continuous testing and feedback. We focus on rapid prototyping to validate concepts and refine designs before full-scale production.